MECANUM-WHEELED ROBOT WITH AI-DRIVEN MANIPULATION

MECANUM-WHEELED ROBOT WITH AI-DRIVEN MANIPULATION

Abstract

This study introduces an innovative robotic system that integrates AI vision, a robotic arm, and Mecanum wheels to address challenges in dynamic environments requiring precise navigation and object manipulation. The primary objective is to develop a unified architecture that combines hardware and software for real-time object detection, tracking, and synchronized control of the robotic arm and mobile platform.

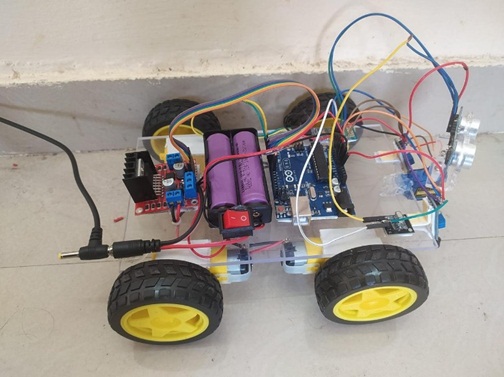

The system features a custom-built mobile platform equipped with Mecanum wheels powered by 12V DC motors, enabling omni-directional mobility for navigating complex terrains. Arduino UNO serves as the central controller and execute control algorithms. The system’s performance was evaluated in a controlled 5m × 5m environment, demonstrating high accuracy in calibration, obstacle avoidance, dynamic tracking.

Results indicate the Mecanum wheels ensured efficient navigation in cluttered spaces. This paper highlights the potential of AI-driven adaptability in robotics, offering applications in manufacturing, healthcare, logistics, and beyond.

Future work could explore enhanced AI models for more complex object recognition tasks, increased payload capacity, and improved energy efficiency, further extending the system's applicability in real-world scenarios.

1. Introduction

The increasing need for automation in various industries, such as manufacturing, logistics, and healthcare, has accelerated tremendous growth in robotics. Yet, the efficient use of robots in dynamic and uncertain environments is still a major challenge. Such environments tend to require accurate navigation, real-time object perception, and dexterous manipulation capabilities

. This study proposes a novel robotic system that will be used to solve these issues through the incorporation of sophisticated artificial intelligence (AI) vision, a general-purpose robotic system, and a highly agile mobile platform with Mecanum wheels. The main aim of this study is to come up with a cohesive architecture that unifies hardware and software elements to operate robustly and efficiently in dynamic environments . The system employs strong control algorithms for synchronized motion planning and execution of the robotic system and mobile platform driving the Mecanum wheels for effective navigation and obstacle avoidance . Taking advantage of the capability of AI, i.e., deep learning techniques, improves object tracking and recognition capability. This involves training and deploying convolutional neural networks (CNNs) for object detection and tracking, enabling the system to adapt to diverse and challenging visual environments . The proposed robotic system incorporates a custom-built mobile platform equipped with four Mecanum wheels powered by 12V DC motors. Mecanum wheels, with their unique roller arrangement, provide omni-directional mobility, allowing the platform to move in any direction without changing its orientation . Voice-controlled robotic devices usually include an Arduino microcontroller, a Bluetooth module, and an Android device to input commands. The Android device sends voice commands through a Bluetooth connection to the microcontroller, which interprets the commands to drive the movements of the robot. The use of a Bluetooth module enables wireless interaction, allowing the robot to be commanded at a distance . To test the performance of line follower robots, different tests are performed, such as straight line, curve line, and junction tests. The tests determine how well the robot can follow varying path configurations. Successful execution of these tests signifies that the robot can successfully accomplish its intended navigation functions, despite the possibility of technical enhancements at all times . Agricultural robots are applied in various applications, ranging from planting to harvesting, as well as precision spraying. They utilize sophisticated technologies like computer vision, machine learning, and sensor fusion to undertake activities of high accuracy .2. Research methods and principles

Voice-operated robotic systems based on Arduino microcontrollers have attracted considerable interest because of their possible uses in environments that are inaccessible or dangerous to humans. The systems utilize voice commands to operate robotic movements, providing a hands-free and user-friendly interface for users.

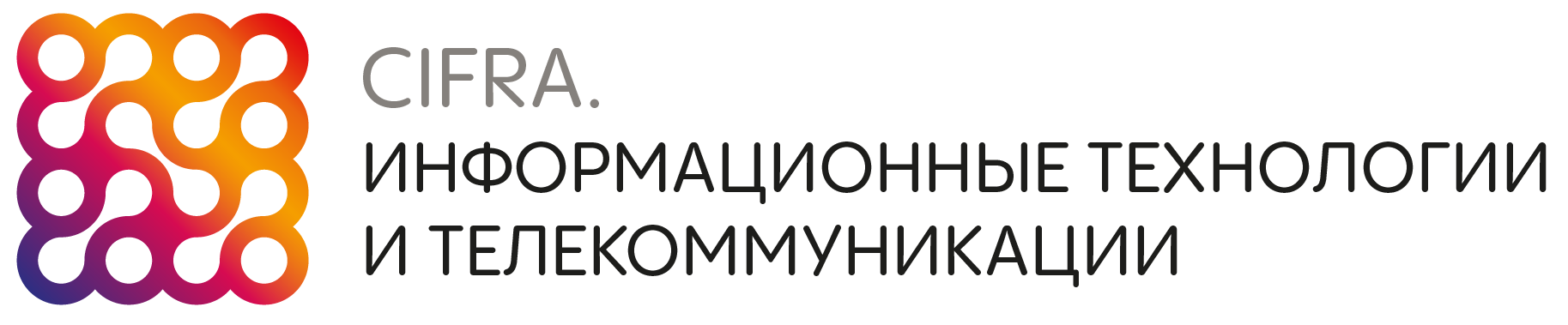

Figure 1 - Block diagram of a Line Follower Robot

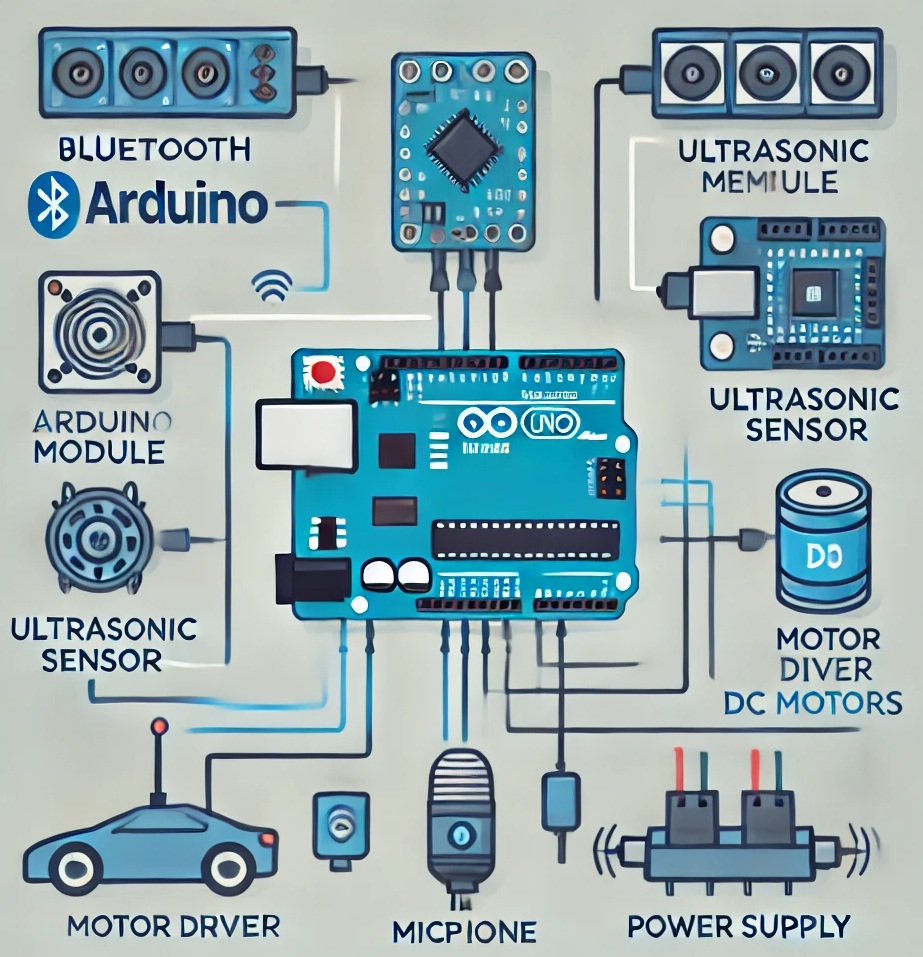

Figure 2 - Line Follower Robot controlled by a smartphone using MIT App Inventor

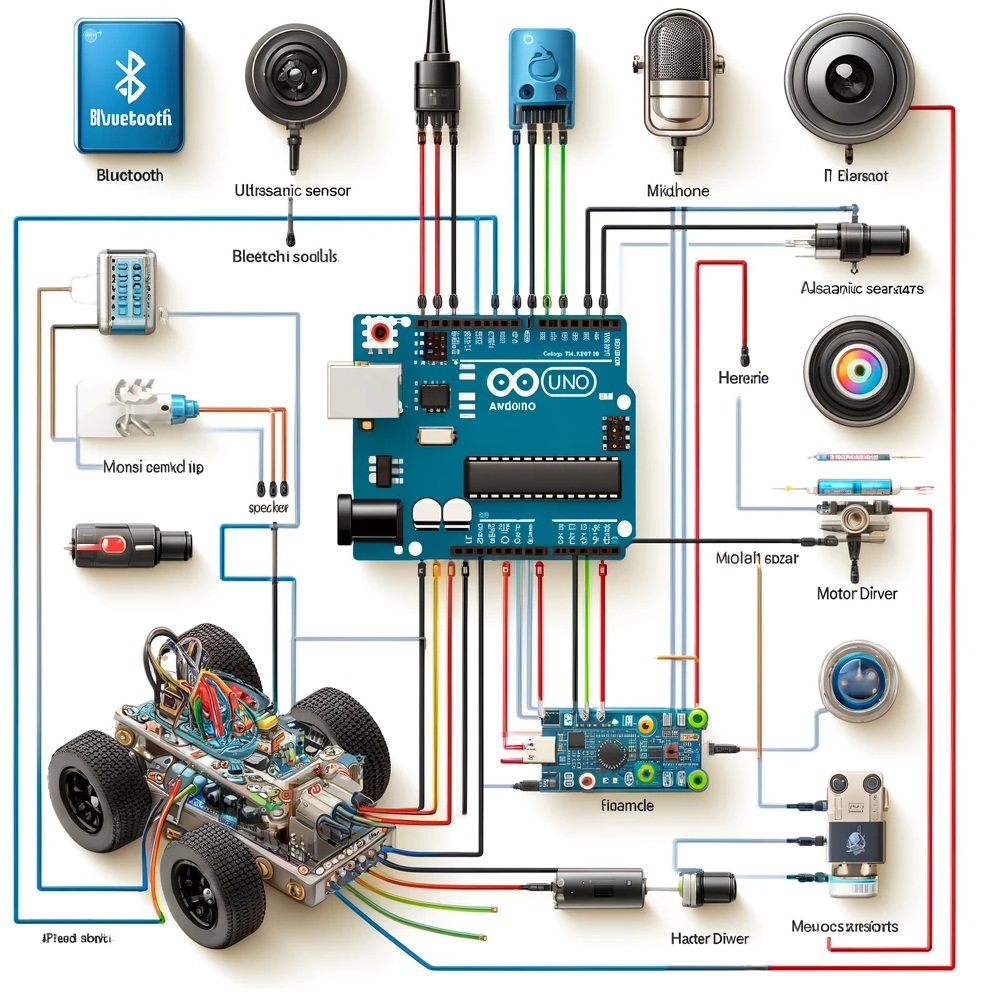

Figure 3 - MIT App Inventor interface

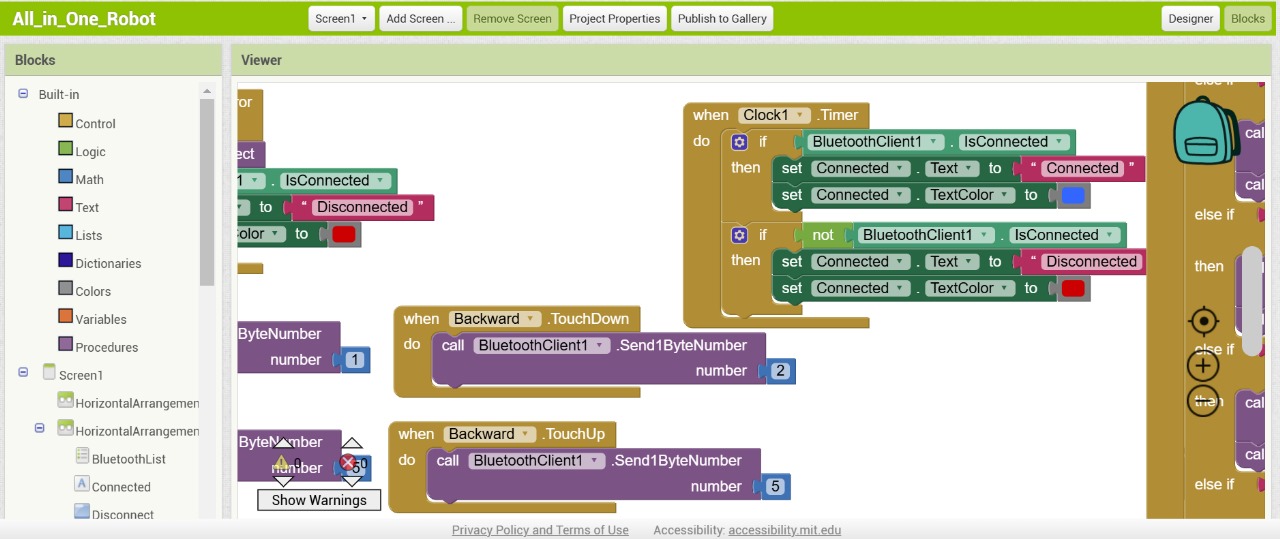

Figure 4 - Development environment of MIT App Inventor

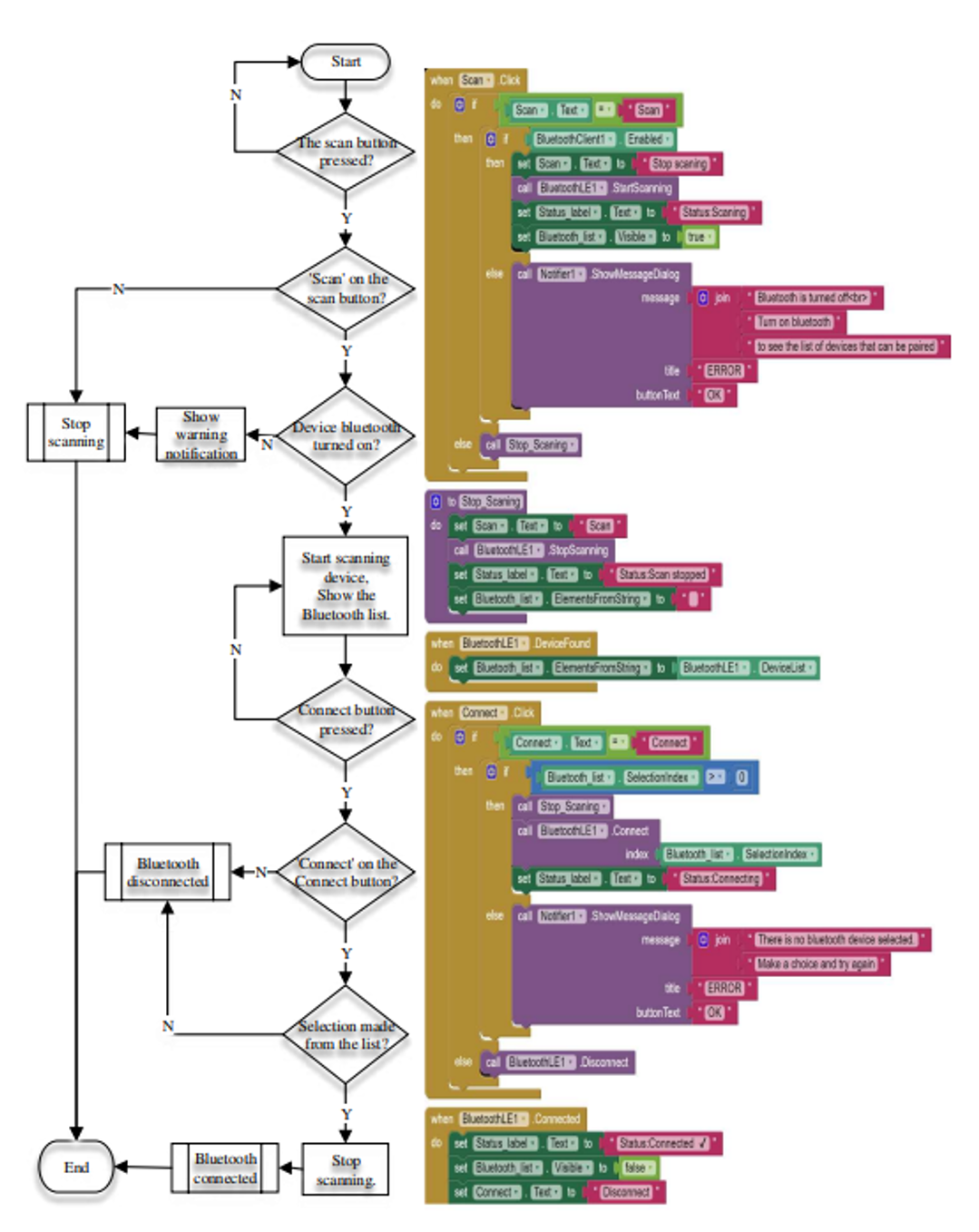

Figure 5 - Bluetooth connection process

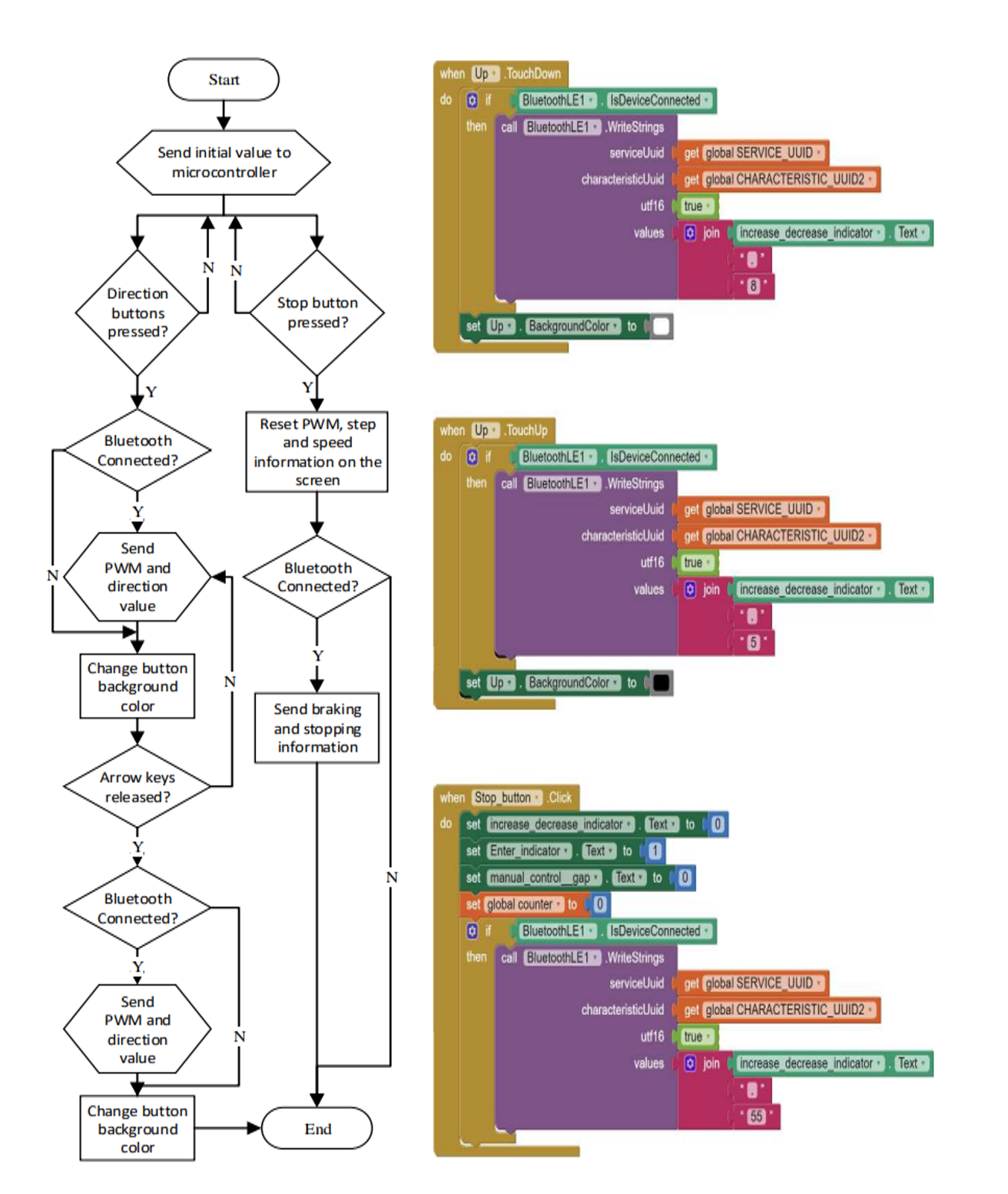

Figure 6 - Control logic for the proposed system

3. Main results

Voice-controlled systems are especially helpful in controlling electronic devices, where users can turn on or off devices with voice commands via a Bluetooth connection on a mobile phone. This method not only makes it easy to control electronic devices but also assists in saving electricity by turning off devices when they are not in use. Further, voice-controlled robots with object identification and picking skills are also in the making to further augment automation in sectors like warehousing and healthcare, illustrating the adaptability and potential of these systems.

Figure 7 - Line follower robot prototype model

4. Discussion

The system controlled by Bluetooth performed successful operation based on the designed flowchart. Direction button and stop button input from the user was successfully converted into control signals, and a stable Bluetooth connection provided consistent communication with the microcontroller. The system displayed precise motor control, responding well to direction changes and performing the stop command well. Visual feedback through color-changing button colors and on-screen data improved user experience and awareness. Simple error handling mechanisms were implemented to deal with Bluetooth disconnections, providing safe operation by suspending commands until reconnection occurred. In general, the system proved successful, offering an intuitive and robust interface for the control of a microcontroller-based system over Bluetooth.

5. Conclusion

Voice-controlled robots have numerous applications, including military operations, home security, rescue missions, and medical assistance. They are particularly useful in situations where human presence is risky or impractical. They are also useful in helping disabled people, allowing them a method of controlling devices without physical interaction. Although existing systems exhibit good voice control, there are still issues in enhancing voice recognition accuracy, particularly in noisy settings. Future studies may address how to make voice recognition more robust and increase the capability of such robots to accomplish more sophisticated tasks. Moreover, incorporating more advanced technologies like natural language processing could further enhance human-robot interaction.